brinell hardness test uses|how to calculate brinell hardness : fabrication The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to . WEB11 Out 1947 a 28 Ago 1952. Ten Cel Inf Miguel Cardoso. 04 Jan 1946 a 11 Out 1947. Este trabalho está licenciado com uma Licença Creative Commons - Atribuição-CompartilhaIgual 4.0 Internacional. A Escola de Sargentos das Armas (ESA), Escola Sargento Max Wolf Filho, é estabelecimento de ensino superior (Nível Tecnlogo) do Exército Brasileiro.

{plog:ftitle_list}

Para editar o convite para Chá de Bebê Chuva De Amor, você só precisa ter no seu computador ou laptop a versão mais recente do Adobe Acrobat Reader.Você pode baixá-lo grátis aqui : adobe reader convite de Chá de Bebê de Chuva De Amor grátis, personalize, imprima com excelente resolução de imagem, você pode criar e montar seu próprio .

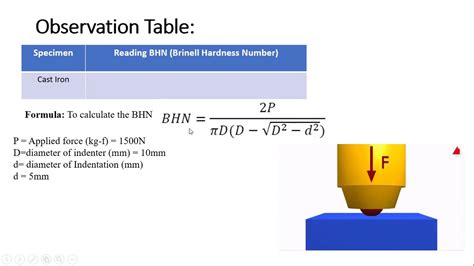

how to calculate brinell hardness

The Brinell hardness test is used to measure the hardness of light metals like lead and tin, also hard metals like steel and iron. Conclusion: In this article, we have seen the Brinell hardness test and its two different methods – .The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .

gas analyzer panel

The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests.The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .The Brinell hardness test is used to measure and inspect materials with rough surfaces such as forgings and casting because you cannot use other methods to inspect them. This is because this method uses a large indenter (usually 10 mm) which averages the rough surface of the test piece for better results. It is also used to assess the hardness . ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS.When is the Brinell hardness test used? Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested.

The Brinell hardness test is used to measure hardness of materials, particularly metals. It has a range of applications, such as ensuring quality control in manufacturing, choosing the appropriate materials in engineering and design, and .The Brinell hardness test method as used to determine Brinell hardness is defined in ASTM E10. It is typically used to test materials with a structure or surface too coarse to be tested by any other test method, for example castings and forgings. Brinell tests often use a very high test load (3000 kgf) and a 10mm diameter indenter so that the . The Brinell hardness test uses a spherical indenter which is pressed, by a precisely controlled force – most commonly 3,000 kgf – into the material being measured. The force builds between two and eight seconds then is sustained for several more to ensure that the indentation is a plastic deformation (see footnote). The diameter of the .Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 .

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; Shore Hardness Testing: Uses the principle of measuring the resistance of a material to indentation; Advanced Techniques in Hardness .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .Principle and Theory of Brinell Hardness Test. Brinell hardness testing uses a known-sized ball with a diameter of 10mm and is pressed into the material with a specified amount of force. The smallest indentation made into the material is then measured and recorded. Based on the initial and final diameters of the indentation, the percent of . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via .

The Brinell hardness test is a widely used method for assessing the hardness of materials. This chapter will outline the step-by-step procedure for conducting a Brinell hardness test, highlighting the key elements and considerations involved. 1. Preparation of the Specimen.Application of Brinell Hardness Test. Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell method. As the Brinell test uses relatively high loads, and therefore relatively large indent, it is frequently used to determine the hardness of the material which has . The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. It does so by pressing a hard ball indenter into the surface of the material under a specified load and calculating the hardness based on the size of the indentation. This test is crucial for assessing metal and alloy material .The Brinell hardness test is a widely used method for assessing the hardness of materials. This chapter will outline the step-by-step procedure for conducting a Brinell hardness test, highlighting the key elements and considerations involved. 1. Preparation of the Specimen.

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:

The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. . Brinell hardness testing is typically used in testing aluminum and copper alloys (at lower forces) and steels and cast irons at the higher force ranges. As the Brinell test uses relatively high loads, and therefore relatively large indent, it is frequently used to determine the hardness in circumstances where the overall material properties are .

Brinell hardness testing also uses a hard spherical indenter, but as already mentioned, rather than measuring depth, measures the diameter of the indentation. Vickers and Knoop hardness tests use a diamond-shaped or pyramidal indenter, where the diagonals of the indentation are measured, and the hardness value is calculated based on the applied . Brinell Hardness Test was the first used and is a widely accepted hardness test. In this article we are going to dig a little deeper into explaining the Brinell Hardness Test. J.A. Brinell proposed first proposed the hardness test in 1900. Brinell’s desire to have a consistent and fast means of determining material hardness grew during his .

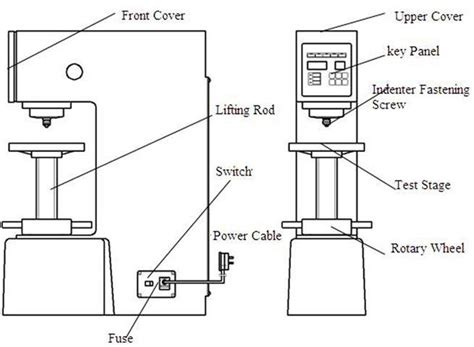

brinell hardness testing machine diagram

brinell hardness testing charts

process gas analyzers

brinell hardness tester diagram

SUMMARY. REVIEWS (0) You are reading Solo Auto-Hunting manga, one of the most popular manga covering in Action, Adventure, toons genres, written by Black Seed .

brinell hardness test uses|how to calculate brinell hardness